WORK WITH THE EXTRUSION EXPERTS™

Vertically-Integrated Capabilities | Decades of Extrusion Experience | World-Class Facilities

- New Capability …Variable Surface PTFE Spiral Heat Shrink Tubing protects products from heat, shock, corrosion, moisture, and other challenging conditions.

LEARN MORE

- Our PTFE Spiral Heat-Shrink Tubing provides a protective covering that resists heat, shock, corrosion, moisture, and other extremes.

READ MORE

- Meeting Our Customers Where They Are ✔ out our tradeshow schedule for 2025.

VIEW SCHEDULE

Get A World of Extrusion Capabilities in One Resource

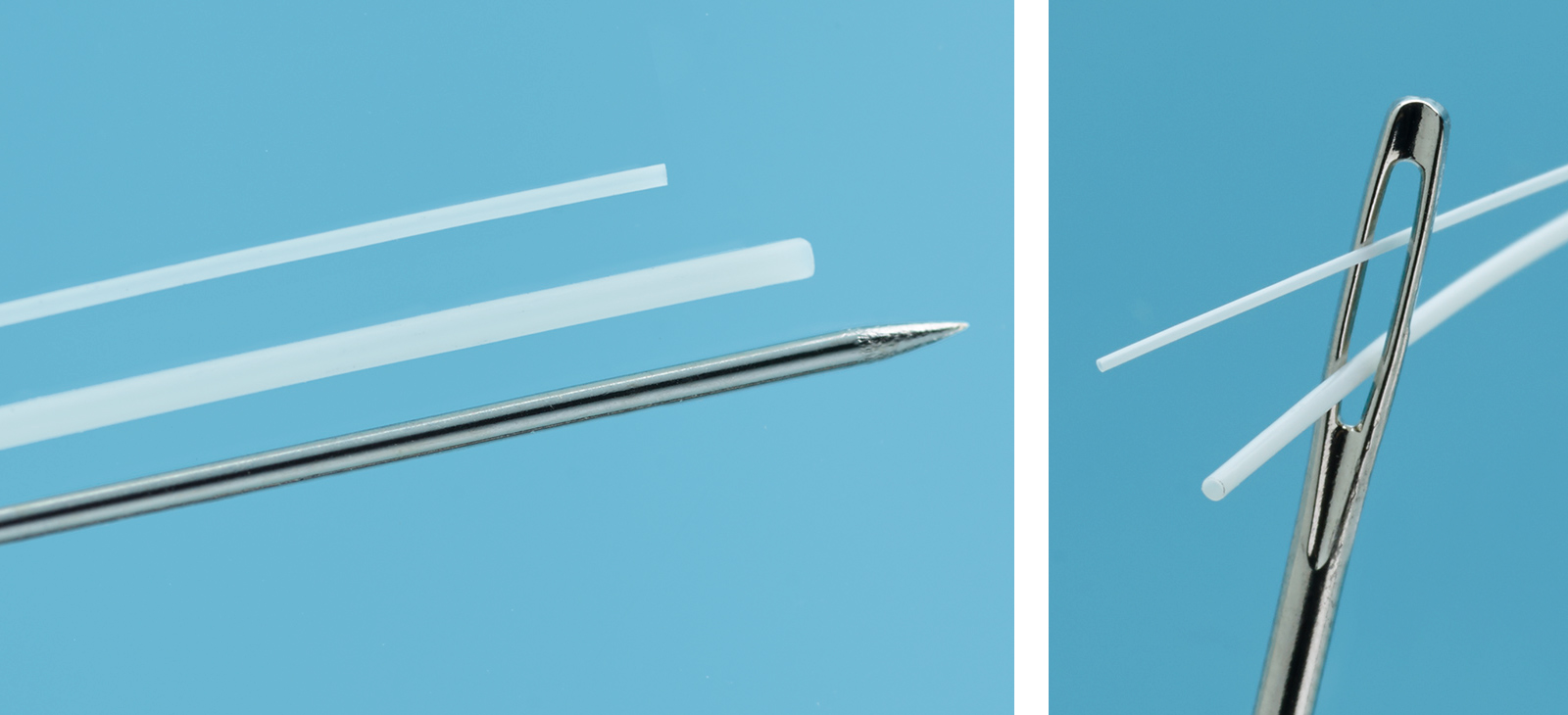

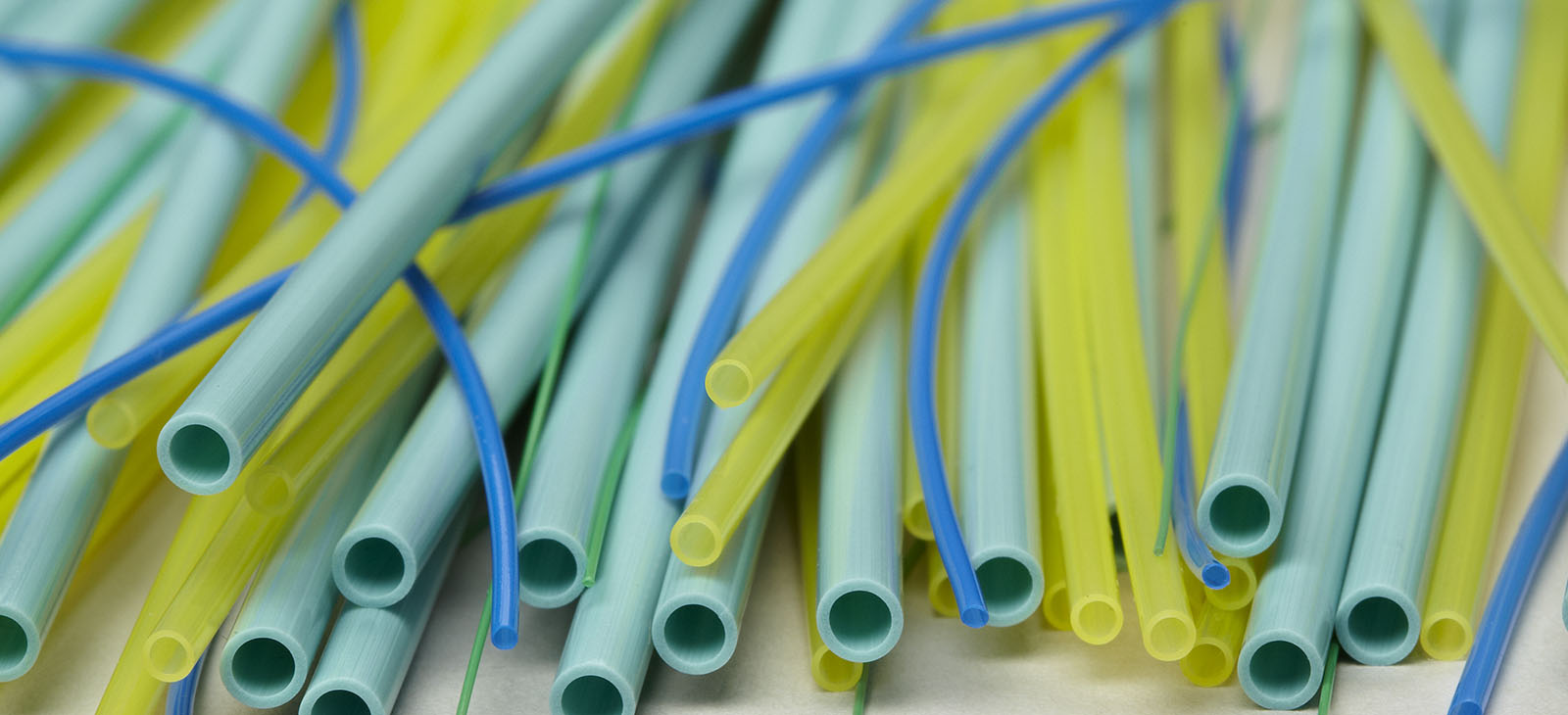

Teleflex Medical OEM is a global leader for precision extrusion in PTFE, FEP, PEEK and other high-performance fluoropolymers and thermoplastics. From heat-shrink tubing to multi-lumen tubing to ultra-thin PTFE liners, we produce extrusion with outstanding tolerance control, length accuracy, and concentricity.

We extrude fluoropolymers and thermoplastics to some of the tightest tolerances, with additional heat-shrink and etching capabilities. We can also fabricate braid- and coil-reinforced tubing in a broad selection of materials, sizes, and wall thicknesses. Co-extrusions are yet another area of expertise – for encapsulated stripes and multiple layers, for over coating of wires, and for combining dissimilar materials.

Complementing all of this, Teleflex Medical OEM offers leading-edge capabilities such as bonding or welding stem sections, softs tips, and atraumatic tips to tubing sections. Step grinding and center less grinding are available in-house, along with comprehensive finishing operations, including flaring, tipping, drilling, and hub molding.

Our team of highly-qualified engineers, material and polymer experts, and skilled technicians makes Teleflex Medical OEM stand above the rest. You can count on us to focus on design for manufacturability, provide regulatory support, and scale up for manufacturing. Teleflex Medical OEM offers you a true, full service partnership with virtually all the resources required to get your project off the drawing board and into the market.

There are plenty of extrusion suppliers in the world. But only Teleflex Medical OEM offers you a winning combination of vertically-integrated capabilities, deep expertise, decades of experience, and a history of industry-changing innovations. Let’s get to work on your project.

- PTFE, FEP, PEEK, and other fluoropolymers and high-performance thermoplastics extruded to your specifications

- Precision thermoplastic extrusion: ID from 0.012″ to .750″; OD from 0.015″ to 0.850” (Custom sizes available)

- Precision PTFE extrusion: ID from 0.003″ to 0.500″; OD from 0.005″ to 0.520″ (Custom sizes available)

- PTFE: customized tensile strength and elongation properties

- PTFE dip etched tubing

- Heat-shrink tubing

- Balloon tubing

- Micro-extrusion

- Co-extrusion

- Multi-layer tubing

- FEP IV tubing

- Etch-less EFEP co-extrusions

- Composite and catheter tubing

- Profiles and shapes

- Braid and coil reinforcement

- Microbore tubing

- Hybrid tubing

- Single- and multi-lumen tubing

- Radiopaque fillers

- Hydrophilic coating services

- Striped extrusions

- Insert molding and overmolding

- Flaring, tipping, and printing

- Custom compounding, including colors and fillers

- Comprehensive finishing operations