- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

Ultimate Guide to Choosing the Best Fep Heat Shrink Tubing for Your Needs

In the ever-evolving landscape of manufacturing and electrical insulation, choosing the right materials is crucial for performance and longevity. Fep Heat Shrink Tubing has emerged as a preferred choice for many industries due to its exceptional thermal stability, chemical resistance, and electrical insulation properties. According to a 2022 market analysis by Research and Markets, the global heat shrink tubing market is estimated to reach USD 2.5 billion by 2026, with a substantial portion attributed to the demand for Fep Heat Shrink Tubing in critical applications such as aerospace, automotive, and telecommunications.

As businesses strive for enhanced safety and efficiency, understanding the specifications and applications of Fep Heat Shrink Tubing becomes essential. This guide will delve into the various factors to consider when selecting the best Fep Heat Shrink Tubing to meet your unique requirements, ensuring optimal performance and reliability in your projects.

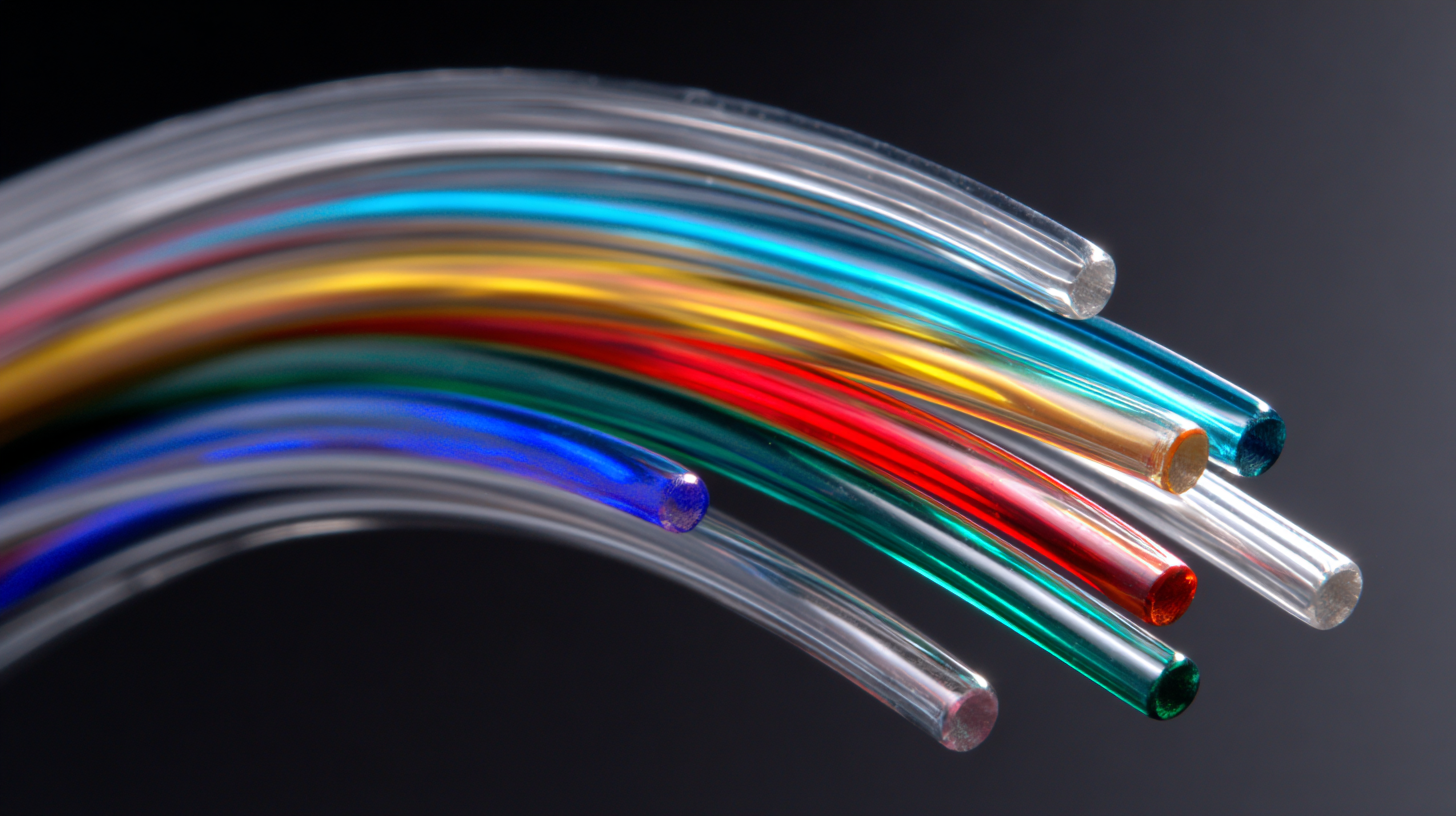

Understanding FEP Heat Shrink Tubing: Key Features and Benefits

FEP heat shrink tubing is becoming increasingly popular due to its unique properties that cater to a wide range of industrial applications. The advantages of FEP (Fluorinated Ethylene Propylene) heat shrink tubing include excellent chemical resistance, high-temperature tolerance, and superior electrical insulation. According to industry reports, the global market for heat shrinkable materials is projected to grow at a CAGR of over 5% from 2023 to 2028, largely driven by the demand for durable and reliable insulation solutions in electronics and telecommunications.

When selecting FEP heat shrink tubing, consider key features such as shrink ratio, operating temperature range, and thickness. A shrink ratio of 2:1 or higher is typically recommended for versatile applications. Additionally, ensure that the tubing can withstand the required operating temperatures, which can range from -70°C to 200°C, depending on the specific needs of your project.

**Tips:** Always check the specifications against your application’s requirements to ensure proper selection. For optimal performance, clean the surfaces where the tubing will be applied, as dust or grease can affect adhesion. If you're working with different cable sizes, consider using a range of sizes to accommodate various applications efficiently.

Different Sizes and Diameters: Choosing the Right Fit for Your Project

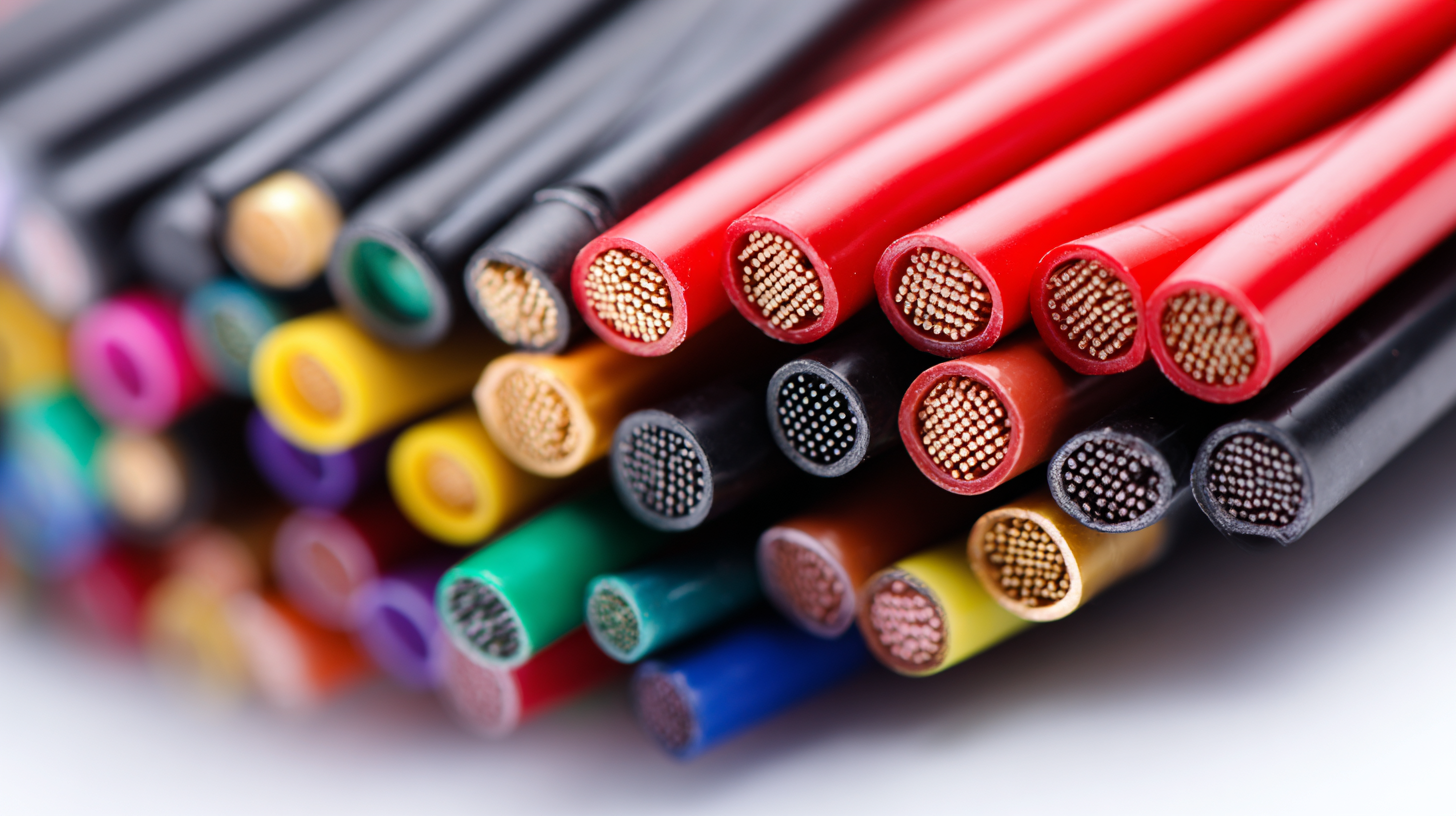

When selecting FEP heat shrink tubing, understanding the various sizes and diameters is crucial for ensuring a proper fit for your specific project. According to industry reports, FEP tubing typically comes in diameters ranging from 0.5mm to 100mm, catering to a wide array of applications in aerospace, automotive, and electronics sectors. The correct diameter not only guarantees optimal insulation but also enhances resistance to chemicals and temperatures, making it ideal for sensitive electronic components.

**Tip:** Before purchasing, measure the dimensions of the components you need to insulate. It's a useful practice to select a diameter that allows enough room for the tubing to shrink without straining the component underneath. Additionally, keep in mind that FEP heat shrink tubing generally shrinks at a ratio of 2:1 or 3:1, depending on the product line. This means that a larger diameter tubing can be shrunk down significantly to fit snugly over your components.

Another critical factor is wall thickness, which can range from 0.05mm to 2.0mm. Bulkier applications like automotive harnesses may require thicker tubing for added protection against abrasion and environmental factors. For more delicate applications, thinner tubing often suffices, thus preserving the compact design of electronic assemblies.

**Tip:** Always consult the manufacturer's specifications for information on wall thickness and shrink ratios. This ensures that you achieve the right balance between protection and flexibility, catering to the demands of your specific application.

Heat Shrink Tubing Sizes and Their Applications

Thermal Performance: Evaluating the Heat Resistance of FEP Tubing

When selecting FEP heat shrink tubing, thermal performance is a crucial factor that should not be overlooked. The heat resistance of FEP (fluorinated ethylene propylene) tubing generally ranges from -200°C to 200°C, making it suitable for various high-temperature applications. This versatility allows for effective insulation in environments that experience extreme fluctuations in temperature. When evaluating FEP tubing, it's important to consider the specific temperature requirements of your project, as exceeding these limits can lead to performance issues.

When selecting FEP heat shrink tubing, thermal performance is a crucial factor that should not be overlooked. The heat resistance of FEP (fluorinated ethylene propylene) tubing generally ranges from -200°C to 200°C, making it suitable for various high-temperature applications. This versatility allows for effective insulation in environments that experience extreme fluctuations in temperature. When evaluating FEP tubing, it's important to consider the specific temperature requirements of your project, as exceeding these limits can lead to performance issues.

Tips: To ensure optimal selection, conduct a thorough analysis of the temperatures your application will encounter. Consider not only the maximum temperature but also potential spikes and prolonged exposure scenarios. Additionally, take note of the shrink ratio—higher shrink ratios can provide better fit and insulation properties, essential for applications requiring tight seals.

Other thermal properties, such as thermal conductivity and dielectric strength, also play a significant role in performance. FEP tubing typically maintains stability under heat, but consulting technical datasheets can provide specifics tailored to your needs.

Tips: Look for suppliers who offer detailed product specifications, as this will help you compare different FEP heat shrink tubes effectively. Don't hesitate to reach out to manufacturers for recommendations based on your temperature thresholds and application specifics.

Chemical Resistance: Ensuring Durability for Various Applications

When selecting FEP heat shrink tubing for your projects, understanding its chemical resistance is crucial to ensure durability across various applications. FEP, or Fluorinated Ethylene Propylene, is renowned for its high thermal stability and outstanding chemical resistance. According to a recent report by the Materials Research Society, FEP tubing can withstand exposure to a wide range of substances, including acids, bases, and organic solvents, making it ideal for use in chemical processing, telecommunications, and medical equipment.

**Tip:** Always consider the specific chemicals your application will encounter. Conduct a compatibility test to confirm that FEP will not degrade when in contact with those substances. Proper indexing can save time and money by preventing premature failure of the tubing.

Another essential aspect to consider is the operating temperature range. FEP heat shrink tubing remains effective in temperatures from -80°C to +200°C. This extensive range means that it can perform well in both high-heat and cryogenic applications. A report by the American Society for Testing and Materials highlights FEP’s ability to retain its properties under extreme conditions, ensuring reliability in critical situations.

**Tip:** Evaluate the environmental conditions of your application, such as temperature fluctuations and exposure to chemicals, to select the right thickness and diameter for your FEP tubing. Matching your tubing dimensions with application requirements can significantly enhance performance.

Ultimate Guide to Choosing the Best Fep Heat Shrink Tubing for Your Needs - Chemical Resistance: Ensuring Durability for Various Applications

| Property | Description | Typical Applications | Chemical Resistance |

|---|---|---|---|

| Temperature Range | -55°C to 150°C | Automotive, Aerospace | Excellent resistance to most solvents |

| Shrink Ratio | 2:1 | Electrical applications, Connectors | Good resistance to acids |

| Flame Retardant | Yes | Marine, Industrial | Resistant to many oils and fuels |

| UV Resistance | Yes | Outdoor applications | Stable against UV radiation |

| Flexibility | High | Robotics, Electronics | Resistant to deformation under stress |

Installation Tips: Best Practices for Applying FEP Heat Shrink Tubing

When it comes to applying FEP heat shrink tubing, proper installation is essential to ensure optimal performance and longevity. First, always start with a clean surface. Dirt, grease, or moisture can interfere with the adhesive properties of the tubing, leading to inadequate sealing. Use isopropyl alcohol or a similar cleaner to prepare the surfaces before application. This step not only enhances adhesion but also ensures that the tubing shrinks evenly around the component.

Another best practice is to select the appropriate size of tubing for your specific application. The tubing should fit snugly over the item being insulated or protected. When applying the heat, start with a heat gun set to a low temperature, gradually increasing the heat as necessary. Keep the heat source moving to avoid overheating any one area, which can cause the tubing to bubble or burst. Additionally, it’s helpful to use a heat shield for sensitive components nearby, shielding them from excessive heat. With careful preparation and execution, you can achieve a reliable and neat finish with FEP heat shrink tubing.