- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

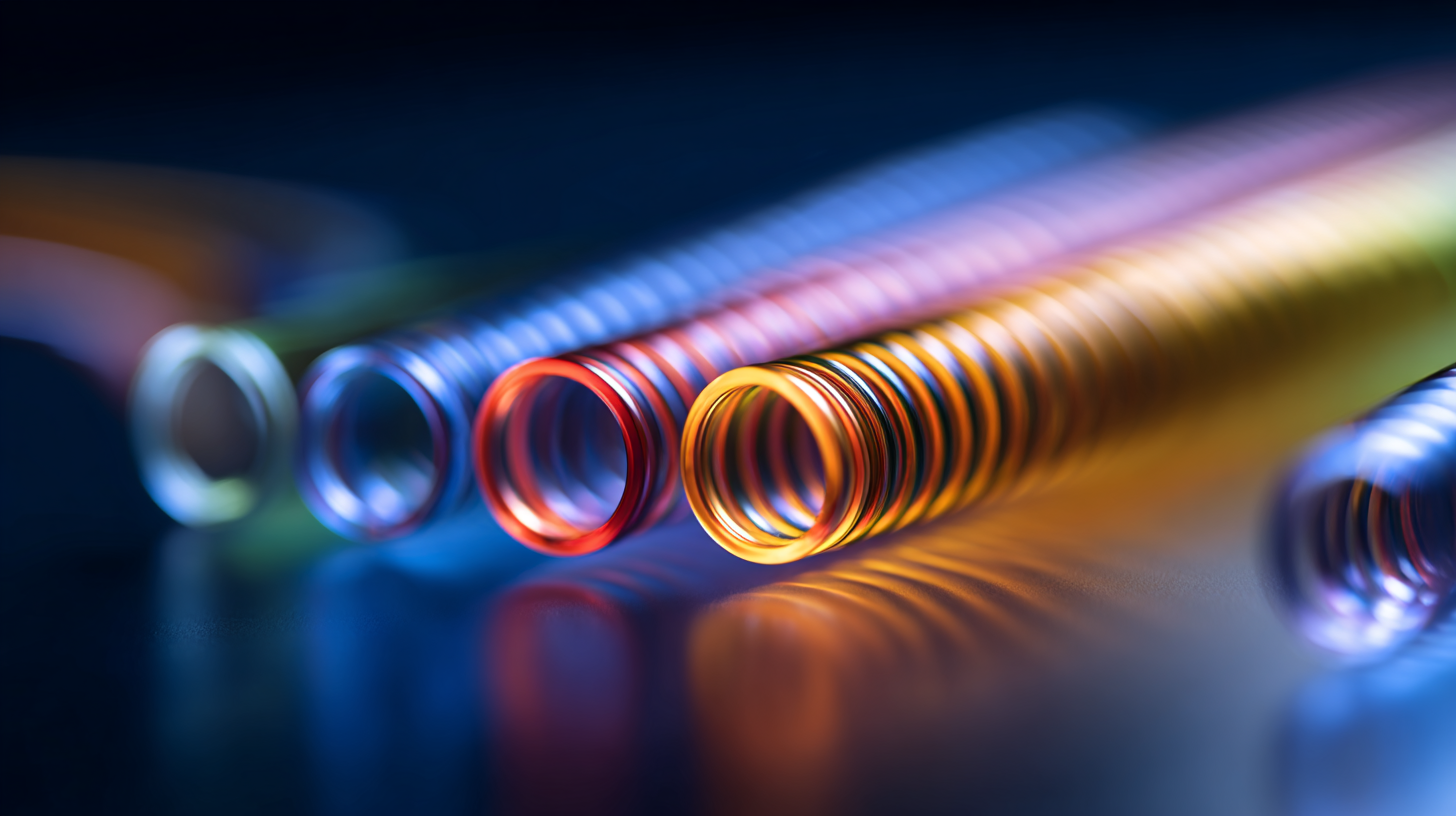

Unmatched Excellence in Chinese Manufacturing of Best Medical Heat Shrink Tubing

In the rapidly evolving landscape of medical manufacturing, "Medical Heat Shrink Tubing" has emerged as a critical component in ensuring the reliability and safety of medical devices. According to a recent report by MarketsandMarkets, the global market for heat shrink tubing is projected to reach USD 12.57 billion by 2025, with a significant portion driven by the increasing demand for medical applications. With stringent regulatory requirements and the necessity for durability and performance in healthcare equipment, manufacturers in China are leading the charge, offering unmatched excellence in production quality. This shift not only highlights the importance of after-sales service advantages but also addresses the concerns of maintenance costs associated with medical device functionality. As the industry continues to innovate, understanding the future trajectory of Medical Heat Shrink Tubing will be crucial for stakeholders aiming to leverage technological advancements and enhance product longevity.

Key Features of Medical Heat Shrink Tubing Produced in China

Chinese manufacturing has established itself as a leader in producing high-quality medical heat shrink tubing, essential for various healthcare applications. One of the key features of this tubing is its exceptional biocompatibility, which ensures that medical devices meet stringent safety standards. This material is specifically engineered to minimize the risk of adverse reactions when in contact with human tissues, making it an ideal choice for sensitive medical environments.

Another notable characteristic of Chinese-made medical heat shrink tubing is its impressive shrink ratio and dimensional stability. With a shrink range typically between 2:1 and 4:1, this tubing can comfortably conform to a variety of shapes and sizes, ensuring effective insulation and protection of medical devices. Furthermore, the tubing is manufactured to withstand elevated temperatures and harsh sterilization processes, providing durability and reliability in critical medical applications. This combination of features showcases the unmatched excellence in China's manufacturing capabilities, driving innovation in the medical field.

Key Features of Medical Heat Shrink Tubing Produced in China

Essential Applications of Heat Shrink Tubing in the Medical Field

Heat shrink tubing plays a crucial role in the medical industry, providing essential protective solutions for various applications. From protecting delicate wires in medical devices to ensuring safe connections in diagnostic equipment, heat shrink tubing enhances both functionality and safety. Its ability to shrink precisely to the shape of the underlying materials not only conserves space but also minimizes the risk of contamination, making it a vital component in environments where hygiene is paramount.

When selecting heat shrink tubing for medical use, it’s important to consider factors such as material properties, shrink ratio, and operating temperature. Tip: Always opt for medical-grade tubing that meets regulatory standards, ensuring reliability and compliance. Additionally, choose colors that allow for easy identification if the tubing will be used in multi-wire configurations.

Heat shrink tubing is also extensively used in sterilization processes. It protects sensitive components during autoclaving and ensures that they remain intact and functional. Tip: For applications requiring exposure to extreme conditions, look for heat shrink tubing with reinforced features, such as high-temperature resistance and chemical durability, to enhance longevity and performance in critical medical settings.

Comparative Analysis: Chinese Manufacturing vs. Global Competitors

In the realm of medical manufacturing, China stands out as a beacon of excellence, particularly in the production of heat shrink tubing utilized in medical applications. A comparative analysis reveals that while global competitors strive to keep pace, China's manufacturing capabilities are rapidly evolving, blending innovation with efficiency. This dynamic has made Chinese firms particularly adept at meeting rigorous international standards, fostering an environment where quality is paramount.

Tips: To identify a reliable supplier, focus on their certifications and quality control processes. Ask for samples to evaluate the product's performance in real-world applications. Engaging with manufacturers that invest in research and development can also provide insights into their commitment to innovation.

Moreover, as industries worldwide adjust to the increasingly competitive landscape shaped by China's advancements, understanding the global supply chain becomes crucial. By evaluating how Chinese manufacturers leverage technology and scale, businesses around the world can gain valuable insights. This knowledge not only aids in benchmarking but also provides strategic direction in sourcing decisions.

Tips: Collaborating with industry experts can enhance understanding of market trends. Stay informed about developments in Chinese manufacturing and be adaptable to shifts that may affect supply chains. Networking with peers in your sector can uncover best practices and emerging opportunities.

Quality Control Practices in Chinese Medical Heat Shrink Tubing Production

In the realm of medical manufacturing, quality control is paramount, especially when it comes to products like medical heat shrink tubing. Chinese manufacturers have honed a variety of rigorous quality control practices to ensure that their products meet international standards. This commitment to quality begins with stringent selection criteria for raw materials, as only the best polymers are used to guarantee durability and effectiveness in medical applications. By employing advanced testing methods, these manufacturers validate every batch before it enters production, ensuring that the final product performs reliably under various conditions.

Additionally, continuous monitoring throughout the production process is vital. Many Chinese facilities incorporate state-of-the-art technology and skilled personnel to oversee manufacturing. Regular audits and inspections are conducted, allowing for immediate adjustments to prevent any potential defects. Furthermore, adherence to international certifications, such as ISO 13485, plays a crucial role in reinforcing product reliability and safety in the medical field. This unwavering focus on quality control not only enhances the reputation of Chinese manufacturers worldwide but also instills confidence in healthcare professionals who depend on these essential products for patient care.

Innovations Driving the Future of Medical Heat Shrink Tubing in China

The landscape of medical heat shrink tubing in China is rapidly evolving, propelled by innovative technologies and advanced manufacturing techniques. According to a report by Market Research Future, the medical heat shrink tubing market is projected to grow at a CAGR of 7.5% from 2021 to 2027, highlighting a robust demand propelled by the increasing need for safety and efficiency in medical devices. Chinese manufacturers are at the forefront of this transformation, leveraging state-of-the-art equipment and materials to deliver products that meet stringent international standards.

One of the key innovations driving this growth is the introduction of advanced polymer materials that offer superior thermal stability and biocompatibility. Recent advancements in polyolefin and PVC formulations have resulted in heat shrink tubing that not only provides excellent insulation and protection but also enhances the performance of medical devices. The Chinese market has witnessed a surge in the adoption of custom shrink tubing solutions, allowing manufacturers to tailor products to specific medical applications, thus enhancing both functionality and user experience. As these innovations continue to shape the industry, China's position as a leading provider of medical heat shrink tubing is becoming increasingly prominent.

Unmatched Excellence in Chinese Manufacturing of Best Medical Heat Shrink Tubing

| Dimension | Specification | Material | Applications | Innovations |

|---|---|---|---|---|

| 1.0 mm | Shrink Ratio 2:1 | Polyolefin | Electrical Insulation | Enhanced Adhesion |

| 2.0 mm | Shrink Ratio 3:1 | Fluoropolymer | Medical Devices | Low Temperature Shrinkage |

| 3.0 mm | Shrink Ratio 4:1 | PVC | Wire Harnesses | Biocompatibility Improvements |

| 4.0 mm | Shrink Ratio 2:1 | Polyethylene | Connector Protection | UV Resistance |