- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

Common Issues with Best Fep Heat Shrink Tubing and Their Impact on Performance

Fep Heat Shrink Tubing is a crucial component in numerous industries, particularly in sectors like electronics, aerospace, and automotive, where reliable insulation and protection are paramount. According to a recent industry report by MarketsandMarkets, the heat shrink tubing market is expected to reach $2.1 billion by 2026, growing at a CAGR of 6.8% from 2021. However, despite its widespread use, there are common issues associated with Fep Heat Shrink Tubing that can significantly impact overall performance. Factors such as improper sizing, inadequate application methods, and environmental considerations often lead to insulation failures or reduced durability. Addressing these common pitfalls is essential for maximizing the effectiveness and longevity of Fep Heat Shrink Tubing in critical applications. In this blog, we will explore these common issues and present practical solutions to enhance performance and reliability.

Common Heat Shrink Tubing Materials: A Comparative Analysis

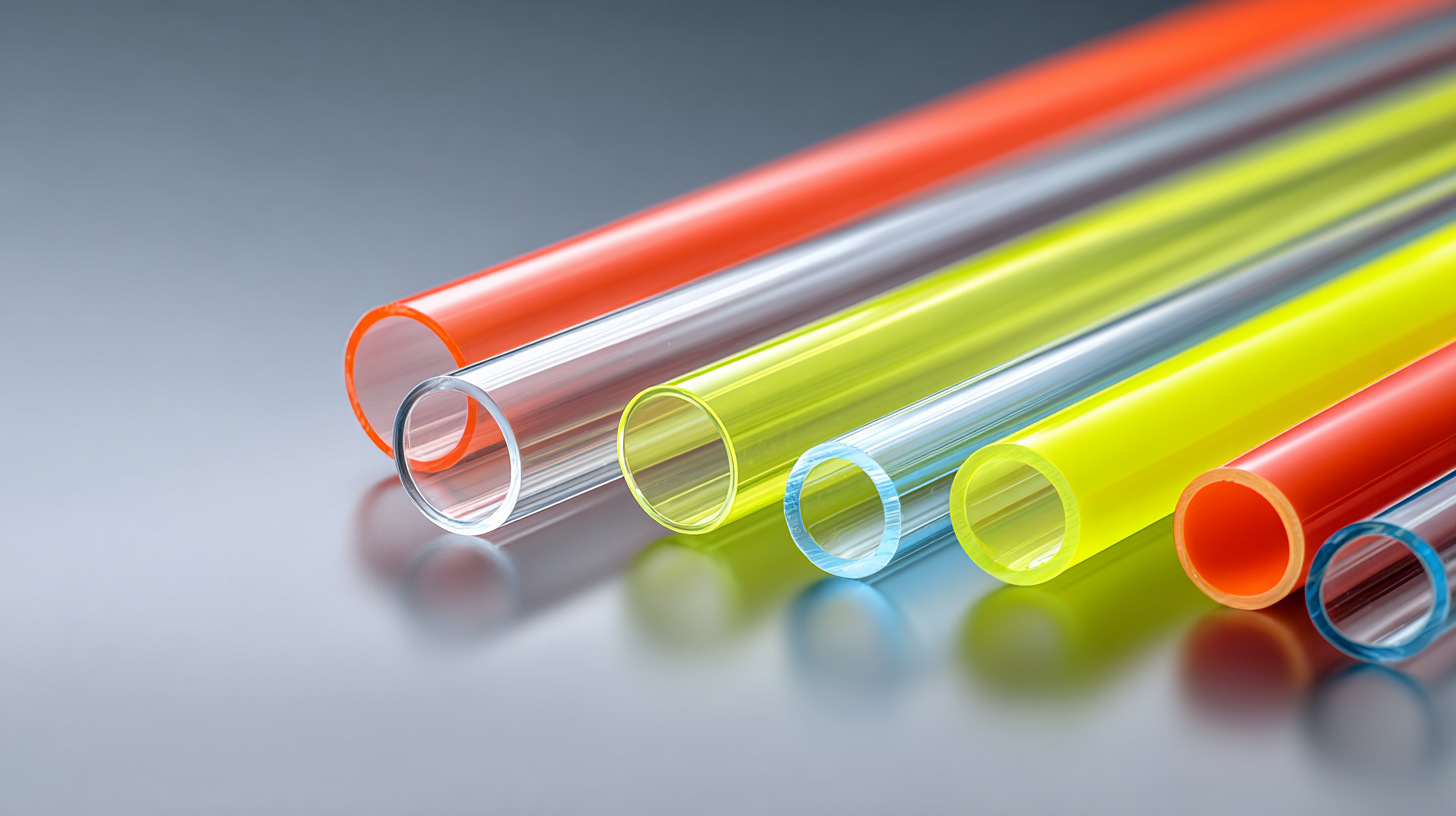

When it comes to heat shrink tubing, understanding the materials used can significantly impact performance. Common materials include polyolefin, PVC, and fluoropolymers, each boasting unique properties that cater to different applications.

Polyolefin is highly favored due to its excellent flexibility, wide operating temperature range, and resistance to chemicals and moisture. This makes it ideal for use in automotive and electronic projects where durability is paramount.

On the other hand, PVC heat shrink tubing is known for its cost-effectiveness and versatility. It provides good electrical insulation and is often used in applications that do not demand high-performance specifications. However, PVC's lower heat resistance compared to polyolefin can be a drawback in high-heat environments.

Fluoropolymer tubing, while typically more expensive, excels in extreme conditions, offering superior chemical resistance and electrical insulation properties. This makes it a go-to choice for aerospace and military applications, where reliability is non-negotiable. By understanding these materials and their attributes, users can make informed decisions that enhance the efficacy of their heat shrink tubing projects.

Durability Challenges in FEP Heat Shrink Tubing and Their Performance Effects

When it comes to FEP heat shrink tubing, durability challenges often arise that can significantly impact performance. Factors such as exposure to extreme temperatures, chemicals, and mechanical stress can compromise the integrity of the tubing, leading to potential failures in applications that require reliable insulation and protection. These issues necessitate careful consideration when selecting materials for heat shrink applications, as the right choice can enhance overall system performance and longevity.

One emerging alternative to consider is flexible, thin-wall heat shrink tubing, which effectively eliminates the FEP reflow process. This innovation not only streamlines the supply chain but also reduces environmental impact. It provides a robust solution for jacketing laser-cut hypotubes, ensuring long-lasting protection while addressing common durability concerns associated with traditional heat shrink tubing.

**Tips:** When selecting heat shrink tubing, always assess the specific environmental and mechanical conditions it will face. Ensure compatibility with the materials to prevent degradation over time. Additionally, consider using newer materials that eliminate complex processing steps, as they often provide enhanced performance and sustainability—key factors in any modern application.

Common Issues with Best Fep Heat Shrink Tubing and Their Impact on Performance - Durability Challenges in FEP Heat Shrink Tubing and Their Performance Effects

| Issue | Impact on Durability | Potential Solutions |

|---|---|---|

| Chemical Resistance | Weakening of material leading to failure over time | Use higher-grade materials with improved chemical resistance |

| Thermal Stability | Deformation or melting under high temperatures | Select FEP with higher thermal resistance ratings |

| UV Resistance | Brittleness and cracking due to prolonged sunlight exposure | Implement UV stabilizers during production |

| Mechanical Stress | Tears and ruptures under heavy load | Enhance material tensile strength through composite layering |

| Moisture Absorption | Compromised electrical insulation properties | Use low-permeability formulations |

Thermal Resistance: FEP vs. Other Common Heat Shrink Options

FEP heat shrink tubing is known for its remarkable thermal resistance compared to other common options like PVC and polyolefin. This characteristic makes FEP tubing particularly suitable for applications that encounter extreme temperatures. Its ability to withstand higher thermal loads without degrading ensures longevity and reliability in diverse environments. However, it is essential to note that while FEP offers superior thermal resistance, it may not be the most cost-effective choice for all applications.

When selecting heat shrink tubing, consider the specific requirements of your project. If temperature extremes are a concern, FEP is an excellent option. However, for less demanding environments, alternatives such as PVC may provide sufficient protection at a lower cost. Always assess the thermal limits and chemical exposure of your application to select the best material.

Tips: Ensure proper sizing of the tubing to avoid unnecessary stress during the shrinkage process, which can lead to performance issues. Additionally, when working with FEP, using a properly calibrated heat source will ensure an even shrink without damaging the tubing. Lastly, remember to check for compatibility with surrounding materials to avoid any adverse reactions that could affect performance.

Impact of Shrink Ratio on Application Success: FEP Heat Tubing Insights

When it comes to FEP heat shrink tubing, understanding the shrink ratio is crucial for achieving optimal application results. The shrink ratio indicates how much the tubing will contract when heat is applied, and choosing the right ratio can significantly impact the performance of your project. For instance, a tubing with a high shrink ratio may be ideal for irregular shapes, as it can conform tightly around complex surfaces, ensuring better insulation and protection.

Tips: Always measure the diameter of the object to be covered accurately before selecting the shrink tubing. This will help you choose a tubing size that achieves a snug fit after shrinking. Additionally, keep in mind that if the application involves exposure to extreme temperatures or chemicals, a higher shrink ratio may provide the necessary stability and security.

Another critical aspect of FEP heat shrink tubing is its temperature resistance. Some applications require the tubing to withstand higher temperatures, and the chosen shrink ratio should align with these demands. If the tubing does not have the appropriate properties, you may face performance issues like premature failure or insufficient insulation.

Tips: Consider the specific needs of your application, including temperature and environmental exposure, when selecting the tubing. Testing a small section before full application is also advisable to ensure compatibility and effectiveness.

Cost vs. Performance: Evaluating the Best FEP Heat Shrink Tubing Options

When evaluating the best FEP heat shrink tubing options, the balance between cost and performance is crucial for many professionals and hobbyists. While affordable products may seem appealing, they often compromise on performance, leading to issues such as inadequate shrinkage, lower thermal stability, or even reduced chemical resistance. These drawbacks can affect not only the longevity of the heat shrink tubing but also the overall integrity of the project at hand.

Investing in higher-quality FEP heat shrink tubing ensures superior performance and reliability in various applications, from electronics to automotive repairs. The right choice can enhance thermal management and ensure minimal risk of failure, especially in demanding environments. As seen in recent evaluations of tools and materials for crafting and home improvement, selecting high-performance products does contribute to better results, warranting a careful approach to balancing budget constraints with the need for quality and durability.