- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

How to Choose the Right Surgical Needle for Your Medical Procedure

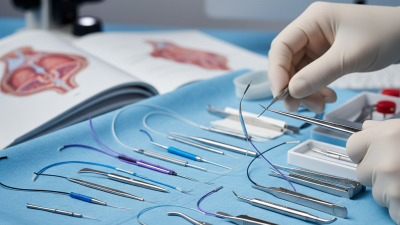

In the field of medicine, the choice of the right surgical needle is a critical determinant in the success of various medical procedures. Surgical needles are not merely tools; they play a vital role in ensuring precision, efficiency, and safety during surgeries and other interventions. With a myriad of options available, healthcare professionals must navigate through the different types, sizes, and materials of surgical needles to select the most appropriate one for each unique circumstance.

The process of selecting a surgical needle involves understanding the demands of the procedure, the type of tissue being sutured, and the desired outcome. Factors such as needle shape, the thickness of the needle (gauged), and the suture material must be carefully considered to enhance the healing process and minimize patient discomfort. This introductory discussion aims to illuminate the significance of making informed choices regarding surgical needles, highlighting their impact on both surgical performance and patient recovery. Ultimately, the right surgical needle can greatly contribute to successful surgical outcomes and improved patient experiences.

Factors to Consider When Selecting a Surgical Needle

When selecting the appropriate surgical needle for a medical procedure, several factors should be taken into account to ensure optimal outcomes. First and foremost, the type of tissue being sutured plays a crucial role. Different tissues, such as skin, muscle, or vascular structures, have varying mechanical properties and healing capacities. For example, a needle with a taper point is ideal for soft tissues, while a cutting needle may be more suitable for tougher tissue like fascia or cartilage.

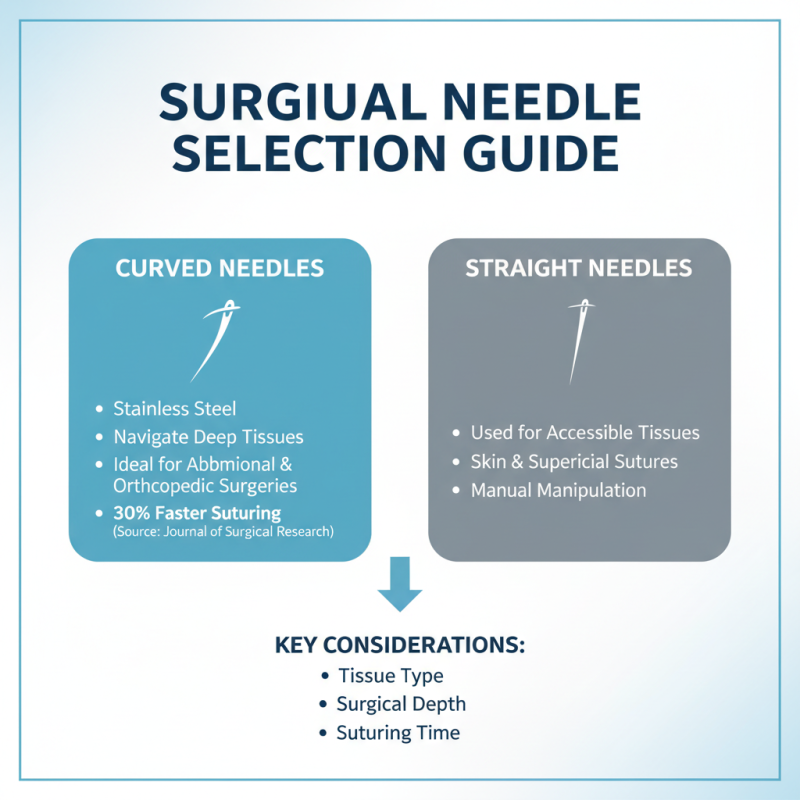

Additionally, the size and shape of the needle should align with the procedure requirements. Needles come in various gauges and lengths, influencing the ease of passage through tissue and the precision of the suturing process. It is also essential to consider the curvature of the needle, as a curved needle provides better control in confined areas, while a straight needle might be more effective in broader surgical fields. Lastly, the choice of material—whether absorbable or non-absorbable sutures—should reflect the desired healing time and tissue response, ensuring that the selected needle meets the specific demands of the surgical intervention.

Additionally, the size and shape of the needle should align with the procedure requirements. Needles come in various gauges and lengths, influencing the ease of passage through tissue and the precision of the suturing process. It is also essential to consider the curvature of the needle, as a curved needle provides better control in confined areas, while a straight needle might be more effective in broader surgical fields. Lastly, the choice of material—whether absorbable or non-absorbable sutures—should reflect the desired healing time and tissue response, ensuring that the selected needle meets the specific demands of the surgical intervention.

Types of Surgical Needles and Their Specific Uses

When selecting the appropriate surgical needle, understanding the various types and their specific uses is crucial. Surgical needles can be broadly classified into two main categories: curved and straight needles. Curved needles, which are often made from stainless steel, are designed to navigate around tissues more efficiently, making them ideal for suturing deeper structures, like in abdominal or orthopedic surgeries. A study published in the Journal of Surgical Research reports that using curved needles can reduce suturing time by up to 30% compared to straight needles.

Additionally, the choice of needle also depends on the type of tissue being repaired. For instance, needles with a taper point are commonly used for soft tissues, while those with cutting edges are preferred for tougher tissues such as skin or fascia. According to data from the American College of Surgeons, the use of appropriate needle types can significantly improve wound healing rates and minimize tissue damage, enhancing overall surgical outcomes. Surgeons must consider needle size and shape carefully to optimize procedure efficiency and patient recovery.

Understanding Needle Sizes and Measurements

Choosing the right surgical needle for a medical procedure is crucial, and understanding needle sizes and measurements plays an essential role in this process. Surgical needles are available in various sizes, commonly defined by their gauge and length. The gauge indicates the thickness of the needle, with higher numbers representing thinner needles. For example, a 12-gauge needle is much thicker than a 30-gauge needle. Selecting the appropriate gauge is vital, as it can influence tissue trauma and healing time.

In addition to gauge, needle length is another important consideration, as it affects the reach and depth of penetration necessary for different procedures. Longer needles may be required for deep tissues, while shorter needles are suitable for surface suturing. It is also essential to consider the type of needle point—cutting or tapered—dependent on the tissue being sutured. For delicate tissues, a tapered point minimizes damage, whereas a cutting needle provides better penetration through tougher tissues. By carefully evaluating needle sizes and their characteristics, healthcare professionals can ensure optimal results during surgical procedures.

Material Composition of Surgical Needles

When selecting the appropriate surgical needle for a medical procedure, understanding the material composition is crucial. Surgical needles are primarily made from stainless steel due to its strength, corrosion resistance, and biocompatibility. According to a report from the American Journal of Surgery, over 85% of surgical procedures in the U.S. utilize stainless steel needles, which can be further categorized into different grades based on their composition and intended use. For instance, needles made from 304 stainless steel are lauded for their durability, while 316 stainless steel is preferred for procedures requiring higher corrosion resistance, especially in the presence of saline environments.

In addition to stainless steel, some needles are coated with materials such as nickel or silicone, enhancing their glide through tissue and reducing trauma during insertion. A study published in the Journal of Clinical Medicine emphasized that properly coated needles can minimize tissue reactivity and result in faster healing times. Moreover, for specific applications, biodegradable materials like polylactic acid are being explored as alternatives, offering the advantage of eliminating the need for suture removal. With the right choice of material composition, surgeons can significantly improve patient outcomes and procedural efficiency.

How to Choose the Right Surgical Needle for Your Medical Procedure - Material Composition of Surgical Needles

| Needle Type | Material Composition | Recommended Use |

|---|---|---|

| Cutting Needle | Stainless Steel | Skin, fascia, and tough tissue |

| Taper Point Needle | Stainless Steel | Soft tissue and vascular procedures |

| Blunt Needle | Plastic or Stainless Steel | Children or delicate tissue |

| Suture Needle | Stainless Steel with Coating | General suturing and closure |

| Chiba Needle | Stainless Steel | Biopsy and aspiration |

Best Practices for Needle Handling and Safety

When it comes to surgical procedures, the importance of proper needle handling and safety cannot be overstated. According to the World Health Organization, improper needle handling can lead to serious complications, including infections and increased post-operative recovery times. A survey conducted by the American College of Surgeons discovered that nearly 30% of surgical site infections (SSIs) can be traced back to inadequate needle safety protocols. To mitigate such risks, healthcare professionals must prioritize the use of safety-engineered devices and adhere strictly to best practices during needle management.

One of the fundamental best practices is the immediate disposal of needles in designated sharps containers after use, minimizing the risk of needle-stick injuries. The Centers for Disease Control and Prevention emphasizes that utilizing puncture-resistant containers can reduce incidents by up to 60%. Additionally, staff education on the proper handling of surgical needles is vital. A report from the Journal of Healthcare Risk Management indicated that hospitals that implemented annual training sessions saw a 45% reduction in needle-stick injuries within two years. By following these best practices, clinicians can enhance safety and ensure better patient outcomes during surgical procedures.

Related Posts

-

5 Essential Factors That Make Medical Sutures a Global Sourcing Priority

-

Essential Factors to Consider When Choosing Best Medical Sutures for Surgical Procedures

-

Exploring Best Medical Sutures in Surgical Practices and Their Unique Applications

-

Exploring the Future of Medical Sutures at the 138th Canton Fair 2025: Trends and Innovations

-

How to Choose the Right Surgical Needle for Your Medical Practice

-

Unleashing China's Manufacturing Prowess in Autoclave Sterilization for Global Buyers