- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

China Manufacturing Thrives Amidst US China Tariffs with Best Ptfe Extrusion Solutions

In recent years, the imposition of tariffs between the United States and China has created a challenging environment for global trade. Nevertheless, China's manufacturing sector has shown remarkable resilience and even growth, particularly in the field of advanced materials and technologies. According to a report by the National Bureau of Statistics of China, industrial production expanded by 6.5% year-on-year in 2022, highlighting the country's adaptability in a fluctuating economic landscape. Among the various sectors thriving amidst these challenges, PTFE extrusion has emerged as a key area of innovation, contributing to China's competitive advantage. This specialized manufacturing process not only caters to diverse industries such as electronics and aerospace but also demonstrates the country's capability to leverage its R&D investments effectively. As global demand for high-performance materials continues to rise, the development of cutting-edge PTFE extrusion solutions is pivotal in ensuring sustained growth for China's manufacturing sector.

China's Resilience: Thriving Manufacturing Sector Amid Tariff Challenges

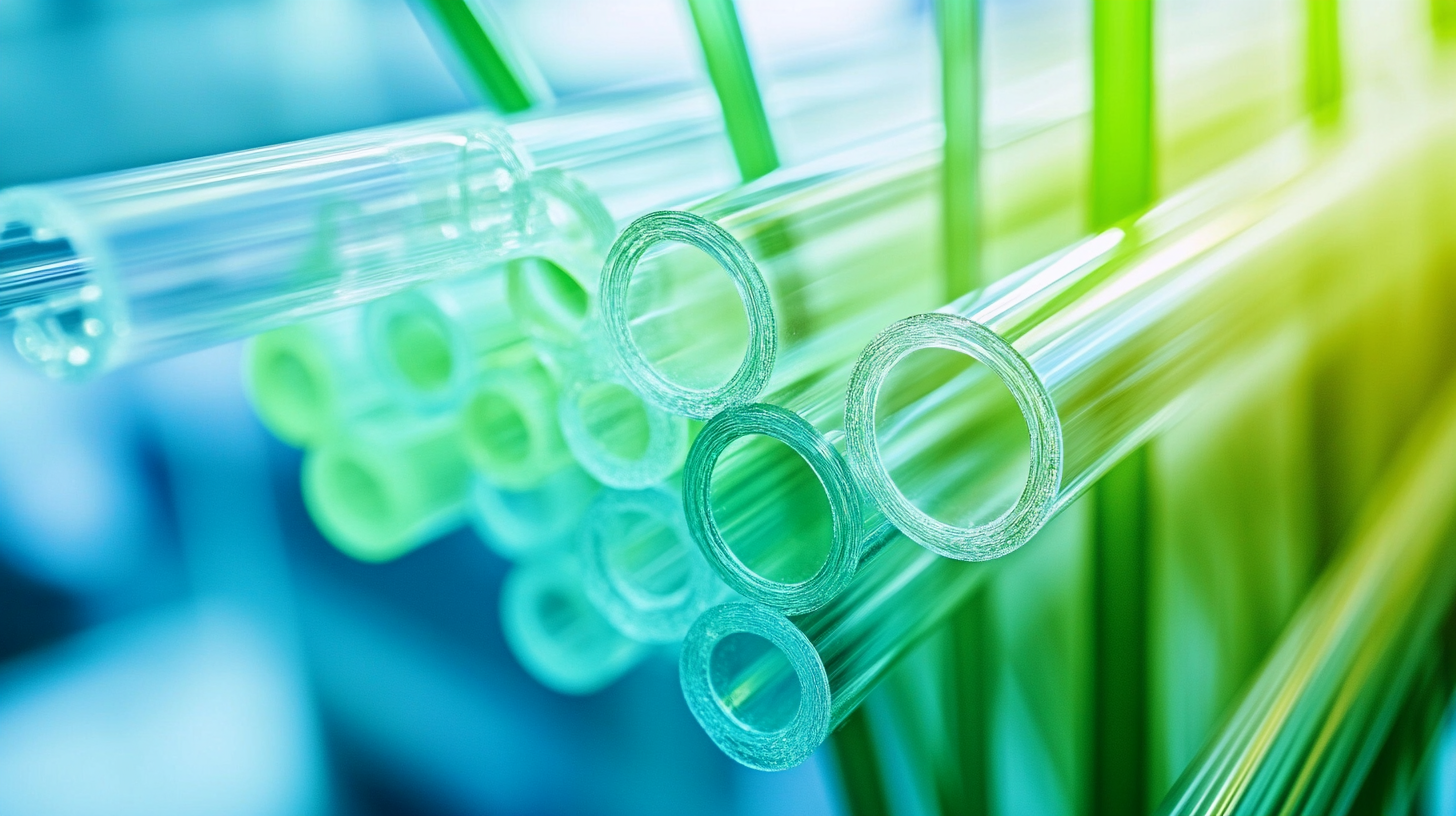

China's manufacturing sector has demonstrated remarkable resilience in the face of ongoing US-China tariffs, maintaining robust growth despite challenging trade conditions. According to a report from the National Bureau of Statistics of China, the manufacturing Purchasing Managers' Index (PMI) consistently remained above the 50-point mark in 2023, indicating expansion. This resilience is particularly evident in the production of high-performance materials such as PTFE (Polytetrafluoroethylene), where Chinese manufacturers have adapted to market demands with innovative extrusion solutions.

In the first half of 2023, the PTFE market alone witnessed a year-on-year growth of 15%, driven by increasing applications in various industries including electronics, chemical processing, and food production. Chinese companies have leveraged advanced technology and competitive pricing, making them preferred suppliers in the global market. As tariffs have made US imports more expensive, many international buyers are turning to China for cost-effective PTFE extrusion solutions, further solidifying the country’s position as a manufacturing powerhouse. This adaptability reflects not only the strength of China’s manufacturing capabilities but also its commitment to remaining a key player in the global economy despite external pressures.

Innovative Strategies in PTFE Extrusion: Meeting Global Demand

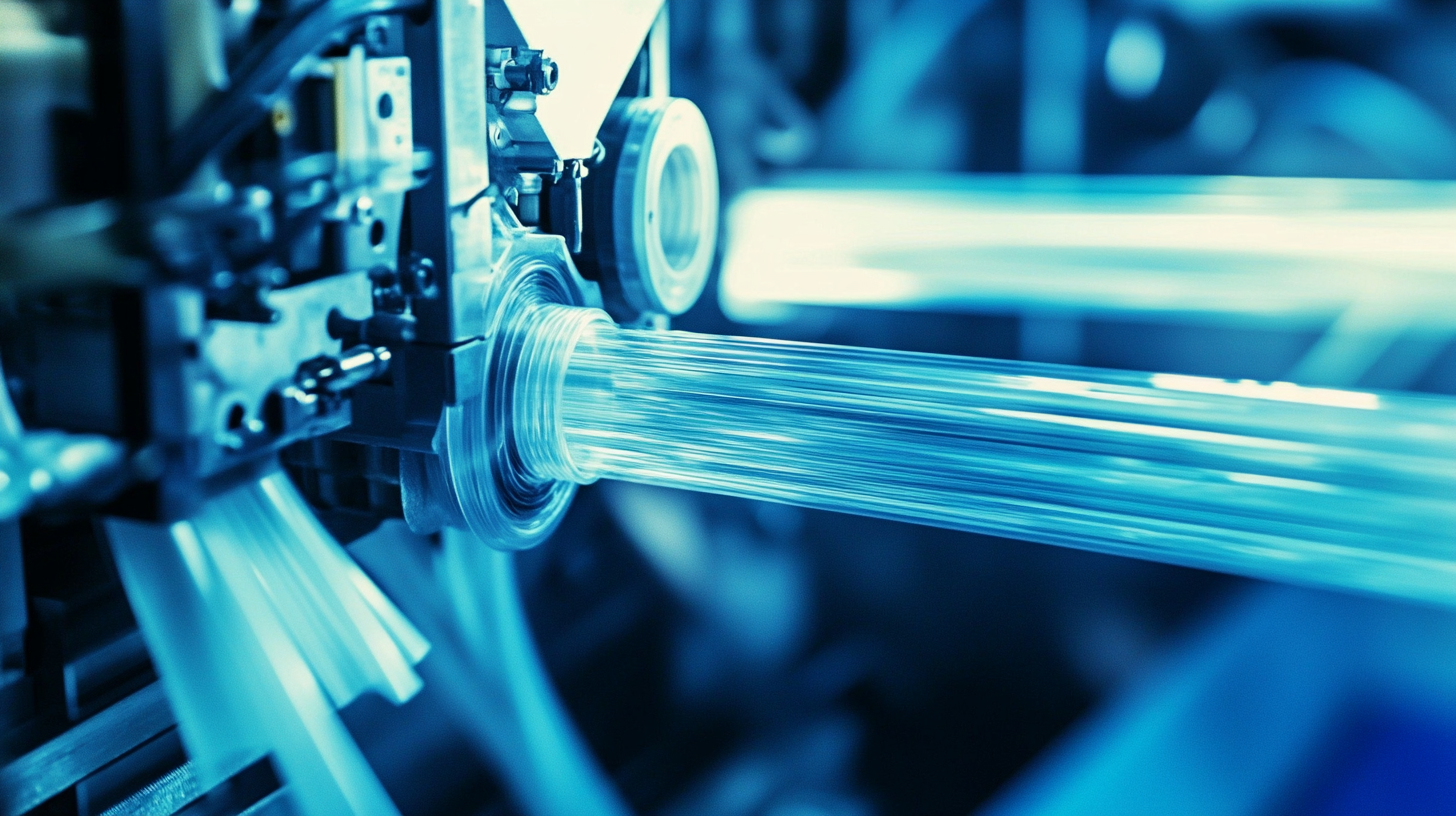

In the current landscape of international trade, facing tariffs has pushed many manufacturers to innovate. Specifically, in the realm of PTFE (Polytetrafluoroethylene) extrusion, Chinese manufacturers have adapted by implementing advanced strategies that not only address the impact of U.S. tariffs but also meet the rising global demand. These innovative approaches include optimizing production processes, integrating cutting-edge technology, and enhancing material quality, allowing them to maintain competitiveness.

One prominent strategy involves investing in automated extrusion systems that streamline manufacturing and reduce operational costs. Additionally, manufacturers are increasingly collaborating with research institutions to develop new PTFE formulations that offer improved performance characteristics. These advancements enable companies to cater to diverse industries ranging from aerospace to electronics, where the demand for high-performance materials is continuously growing. By embracing these innovative strategies, Chinese manufacturers are not only overcoming trade challenges but are also positioning themselves as leaders in the global PTFE market.

China Manufacturing Thrives Amidst US China Tariffs

This bar chart illustrates the growing production of PTFE extrusion in China over the past five years. Despite the impact of US-China tariffs, the demand for high-quality PTFE solutions has increased significantly, showcasing the resilience and adaptability of the manufacturing sector in China.

The Role of Advanced Technology in Supporting China's Manufacturing Growth

China's manufacturing sector continues to flourish despite the ongoing US-China tariffs, largely due to the integration of advanced technology and a commitment to innovation. As highlighted by President Xi Jinping, the nation has placed significant emphasis on cultivating new, high-quality productive forces through scientific and technological advancements. This strategic focus not only enhances operational efficiency but also positions China as a leader in manufacturing solutions, particularly in high-demand areas such as PTFE extrusion.

The adoption of cutting-edge technologies in manufacturing processes has allowed China to streamline production, reduce costs, and improve product quality. Automated systems, artificial intelligence, and data analytics play crucial roles in optimizing manufacturing workflows, enabling factories to respond swiftly to market demands. Furthermore, investments in research and development are fostering a culture of innovation that fuels the creation of high-performance materials and components, solidifying China's reputation in the global manufacturing landscape. This synergy between technology and manufacturing not only supports economic growth but also ensures the country's resilience in a competitive international environment.

| Year | Manufacturing Growth Rate (%) | Exports to US (Billion USD) | PTFE Production (Metric Tons) | Investment in Technology (Billion USD) |

|---|---|---|---|---|

| 2020 | 6.5 | 100 | 15,000 | 10 |

| 2021 | 8.1 | 120 | 18,000 | 12 |

| 2022 | 7.2 | 110 | 20,000 | 15 |

| 2023 | 6.9 | 130 | 22,000 | 20 |

Leveraging Supply Chain Flexibility: China's Competitive Edge

China's manufacturing sector continues to demonstrate remarkable resilience in the face of US-China tariffs, largely attributed to its unparalleled supply chain flexibility. According to a recent report from the International Trade Administration, China's manufacturing output reached approximately $3 trillion in 2022, solidifying its position as a global leader. This dynamic has enabled Chinese manufacturers to rapidly adapt to market shifts, optimizing production processes to mitigate the impacts of tariffs while maintaining competitive pricing.

One key advantage in this landscape is the integration of advanced technologies, such as automation and artificial intelligence, which enhances production efficiency and lowers operational costs. Data from McKinsey indicates that companies that actively embrace digital transformation in supply chain management can increase productivity by up to 30%. The robust capabilities of China's manufacturing sector, especially in industries like PTFE extrusion, allow for quick adjustments to product specifications and inventory management, ensuring timely fulfillment of client demands despite external pressures. This responsiveness not only underscores China's competitive edge but also positions it well for sustainable growth in a shifting global economy.

Future Outlook: Sustaining Growth in a Tariff-Driven Landscape

In the current tariff-driven landscape, China’s manufacturing sector continues to display remarkable resilience and adaptability. According to a report by the China National Bureau of Statistics, the manufacturing Purchasing Managers' Index (PMI) has consistently remained above the critical 50-point level, indicating expansion. This flourishing environment is largely attributed to companies leveraging innovative materials and processes, particularly in PTFE extrusion solutions, which facilitate the production of high-performance components necessary in various industries, including electronics and automotive.

Looking ahead, sustaining growth amidst challenges requires strategic approaches. Industry analyst group ICIS reports that the global demand for PTFE is predicted to grow at a compound annual growth rate (CAGR) of 4.5% through 2026. This trend reflects increasing applications across high-temperature and corrosive environments, showcasing the potential for manufacturers to capture new markets. Companies focusing on process optimization and technological advancement are better positioned to navigate the complexities introduced by tariffs and supply chain disruptions, ensuring their competitiveness in both domestic and international markets.